Ventilation is necessary for a few reasons including:

1. Airtight homes

Homes designed in recent years are more airtight and energy efficient than homes designed in the past. This, unfortunately, results in more harmful pollutants being retained in the home. A proper mechanical ventilation design can help maintain a healthy indoor environment.

2. Biological pollutants

Good ventilation in the home is suggested to avoid moisture and excess build up of biological pollutants such as mold and mildew. Excess pollutants are not only detrimental to your health, but can also lead to the deterioration of structure supports and walls.

3. Volatile organic compounds (VOCs)

VOCs are gases released from building materials, carpets, furniture, and other household items as a result of aging, decomposition, or curing. A good ventilation system will prevent prolonged exposure to VOCs and keep the air in your home fresh and well circulated.

Ideally, an airtight home designed with both continuous and intermittent ventilation will contribute to a healthy and comfortable living environment for your entire family.

Continuous ventilation

Also referred to as general, central, whole-house or primary ventilation, continuous ventilation removes stale air, and provides fresh air to all rooms on a slow, continuous basis. Well-designed, airtight homes should generally use low volume continuous ventilation.

Intermittent ventilation

Sometimes called spot, local or secondary ventilation, intermittent ventilation is used to capture and remove pollutants quickly at the source. The purpose is to exhaust excessive moisture or pollutants before they can spread to other parts of the house. Areas that might require this type of ventilation include the bathroom, kitchen, utility room, exercise room, workshop, garage, and home office.

Other ways to improve indoor air quality before ventilation include:

- Reducing or removing the source of pollutants (paint, solvents, chemicals)

- Using building materials with a low level of toxicity

- Making sure there is an airtight seal between the garage and living quarters if your garage is attached to your house

Installation

Proper fan installation is necessary to optimize performance. The following points outline installation techniques to help achieve optimum performance. For existing construction, depending on the building's structure and the possibility of accessing the ducts, you may not be able to use all of these techniques; however, the more techniques used, the better the performance you can expect from your ventilation fan. In new construction where the walls and ceilings are open, with proper planning, applying these techniques can be relatively easy.

Important

In order to reduce elbows and optimize fan performance, install the fan with the exhaust port pointed in the direction of the termination point. Be sure to use the duct diameter size specified for the selected fan. Reducing the duct diameter (at any point in the duct run) may create substantial static pressure and reduce the fan's performance by as much as 90%.

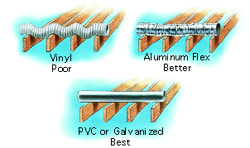

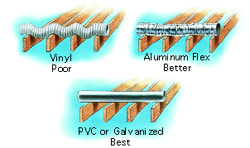

Duct selection

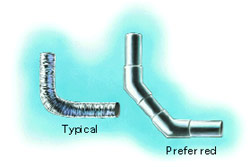

A smooth surface duct allows for optimum airflow. For best results, use galvanized sheet metal or PVC. A flexible aluminum duct is durable, easy to install and often used. However, the ridges in an aluminum flexible duct increase static pressure and can reduce air flow and fan performance. This results in lower CFMs, higher noise levels and greater energy consumption. The degree to which performance is affected depends on the length of the duct, and the number and degree of elbows.

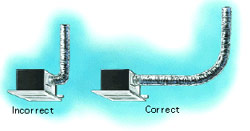

Sagging or weaving a fan duct will also increase static pressure and reduce a fan's performance. When using a flexible aluminum duct, support the entire length of the duct with braces or hangers to keep it as straight as possible for the entire run. If the duct lies across the attic, do not allow it to sag between each joist. Also, avoid serpentine weaving through trusses.

Using a flexible duct made of nylon or vinyl is not recommended due to high static pressure caused by its ridges and curvature.

Elbows

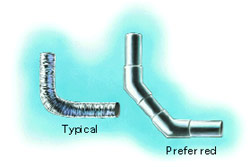

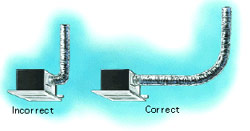

Rule number one is to avoid elbows and bends as much as possible. However, the fact is that many installations require at least one elbow, as shown here. There are two precautions you can take when installing elbows to achieve optimum airflow.

First, allow a 2 - 3 foot straight run out of the fan before the first elbow. This allows airflow momentum to build before passing through the first elbow. An installation that has a 90-degree elbow immediately after the fan exhaust port will cause air to flow back into the fan. This will reduce fan performance and increase noise. Second, use a long radius angle to help ensure optimum airflow and minimum airflow noise.

The shortest smooth, inner surface duct with the least number of elbows will provide optimum fan performance.

|