Isolation Transformer

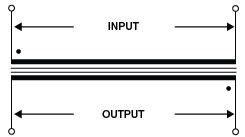

Transformers with primary (input) and secondary (output) windings separated from each other are known as isolation transformers. Under this construction, the input power and the output power are electrically separated by an dielectric insulation barrier.

|

|

| Isolation Transformer |

Advantages of using an isolation transformer

- The primary and secondary winding can be constructed as a step-up or step-down transformer to match the load in the electrical system

- Preventing the equipment from getting spikes and harmonics from the mains

- Safety. There will be no conductive connection between the live part of the circuit and earth. With the isolating transformer, there is no danger in touching the live while the body is earthed.

- By connecting the electrical system safety ground to the neutral conductor on the transformer secondary, it eliminates neutral-to-ground voltage and noise. This resolves reliability problems for microprocessor-based electronics.

Isolating transformers are also the most common kind of transformers for voltage step-up and step-down usage.However, 1:1 ratio transformers, where input and output voltage are the same, are also widely used to solely take advantage of the isolation.

Autotransformer

|

|

|

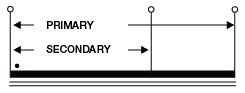

| Step-down Autotransformer | Step-up Autotransformer |

In an autotransformer, the primary and secondary share a common winding. The secondary voltage always has a common terminal with the primary. Step up or down of the voltage is achieved by a tap from the winding measuring from the common end. For example, a secondary tap at 50% of the winding will produce a voltage half of the input.

Advantages of using an Autotransformer

- Lighter in weight and smaller in physical size as it requires fewer windings and a smaller core.

- Less costly compared to an isolation transformer.

- The advantages listed typically are for autotransformer with voltage ratio ranging up to 3:1 voltage or vice versa. Beyond this range, an isolation transformer is usually more economical.

Limitations

- There is no isolation between the primary winding and the secondary winding. Therefore protection of the equipment is dependant on the supply devices.

- As the primary and secondary share a common end, if the neutral side of the primary voltage is not grounded, the secondary side will not be either.

- A failure of the winding insulation of the autotransformer will result in full input voltage applied to the output.