Hydroponics is a subset of hydroculture and is a method of growing plants using mineral nutrient solutions, in water, without soil. Terrestrial plants may be grown with their roots in the mineral nutrient solution only or in an inert medium, such as perlite, gravel, biochar, mineral wool,expanded clay pebbles or coconut husk.

Researchers discovered in the 18th century that plants absorb essential mineral nutrients as inorganic ions in water. In natural conditions, soil acts as a mineral nutrient reservoir but the soil itself is not essential to plant growth. When the mineral nutrients in the soil dissolve in water, plant roots are able to absorb them. When the required mineral nutrients are introduced into a plant's water supply artificially, soil is no longer required for the plant to thrive. Almost any terrestrial plant will grow with hydroponics. Hydroponics is also a standard technique in biology research and teaching.

Origin

Soilless culture

Gericke originally defined hydroponics as crop growth in mineral nutrient solutions. Hydroponics is a subset of soilless culture. Many types of soilless culture do not use the mineral nutrient solutions required for hydroponics.

Plants that are not traditionally grown in a climate would be possible to grow using a controlled environment system like hydroponics. NASA has also looked to utilize hydroponics in the space program. Ray Wheeler, plant physiologist at Kennedy Space Center’s Space Life Science Lab, believes that hydroponics will create advances within space travel. He terms this as a bioregenerative life support system.

Advantages

Some of the reasons why hydroponics is being adapted around the world for food production are the following:

- No soil is needed for hydroponics.

- The water stays in the system and can be reused - thus, a lower water requirement.

- It is possible to control the nutrition levels in their entirety - thus, lower nutrition requirements.

- No nutrition pollution is released into the environment because of the controlled system.

- Stable and high yields.

- Pests and diseases are easier to get rid of than in soil because of the container's mobility.

- Ease of harvesting.

- No pesticide damage.

Today, hydroponics is an established branch of horticulture. Progress has been rapid, and results obtained in various countries have proved it to be thoroughly practical and to have very definite advantages over conventional methods of horticulture.

There are two chief merits of the soil-less cultivation of plants. First, hydroponics may potentially produce much higher crop yields. Also, hydroponics can be used in places where in-ground agriculture or gardening are not possible.

Disadvantages

Without soil as a buffer, any failure to the hydroponic system leads to rapid plant death. Other disadvantages include pathogen attacks such as damp-off due to Verticillium wilt caused by the high moisture levels associated with hydroponics and over watering of soil based plants. Also, many hydroponic plants require different fertilizers and containment systems.[10]

Techniques

The two main types of hydroponics are solution culture and medium culture. Solution culture does not use a solid medium for the roots, just the nutrient solution. The three main types of solution cultures are static solution culture, continuous-flow solution culture and aeroponics. The medium culture method has a solid medium for the roots and is named for the type of medium, e.g., sand culture, gravel culture, or rockwool culture.

There are two main variations for each medium, sub-irrigation and top irrigation[specify]. For all techniques, most hydroponic reservoirs are now built of plastic, but other materials have been used including concrete, glass, metal, vegetable solids, and wood. The containers should exclude light to prevent algae growth in the nutrient solution.

Static solution culture

In static solution culture, plants are grown in containers of nutrient solution, such as glass Mason jars (typically, in-home applications), plastic buckets, tubs, or tanks. The solution is usually gently aerated but may be un-aerated. If un-aerated, the solution level is kept low enough that enough roots are above the solution so they get adequate oxygen. A hole is cut in the lid of the reservoir for each plant. There can be one to many plants per reservoir. Reservoir size can be increased as plant size increases. A home made system can be constructed from plastic food containers or glass canning jars with aeration provided by an aquarium pump, aquarium airline tubing and aquarium valves. Clear containers are covered with aluminium foil, butcher paper, black plastic, or other material to exclude light, thus helping to eliminate the formation of algae. The nutrient solution is changed either on a schedule, such as once per week, or when the concentration drops below a certain level as determined with an electrical conductivity meter. Whenever the solution is depleted below a certain level, either water or fresh nutrient solution is added, A Mariotte's bottle, or a float valve, can be used to automatically maintain the solution level. In raft solution culture, plants are placed in a sheet of buoyant plastic that is floated on the surface of the nutrient solution. That way, the solution level never drops below the roots.

Continuous-flow solution culture

In continuous-flow solution culture, the nutrient solution constantly flows past the roots. It is much easier to automate than the static solution culture because sampling and adjustments to the temperature and nutrient concentrations can be made in a large storage tank that has potential to serve thousands of plants. A popular variation is the nutrient film technique or NFT, whereby a very shallow stream of water containing all the dissolved nutrients required for plant growth is recirculated past the bare roots of plants in a watertight thick root mat, which develops in the bottom of the channel and has an upper surface that, although moist, is in the air. Subsequent to this, an abundant supply of oxygen is provided to the roots of the plants. A properly designed NFT system is based on using the right channel slope, the right flow rate, and the right channel length. The main advantage of the NFT system over other forms of hydroponics is that the plant roots are exposed to adequate supplies of water, oxygen, and nutrients. In all other forms of production, there is a conflict between the supply of these requirements, since excessive or deficient amounts of one results in an imbalance of one or both of the others. NFT, because of its design, provides a system where all three requirements for healthy plant growth can be met at the same time, provided that the simple concept of NFT is always remembered and practised. The result of these advantages is that higher yields of high-quality produce are obtained over an extended period of cropping. A downside of NFT is that it has very little buffering against interruptions in the flow, e.g., power outages. But, overall, it is probably one of the more productive techniques.

The same design characteristics apply to all conventional NFT systems. While slopes along channels of 1:100 have been recommended, in practice it is difficult to build a base for channels that is sufficiently true to enable nutrient films to flow without ponding in locally depressed areas. As a consequence, it is recommended that slopes of 1:30 to 1:40 are used. This allows for minor irregularities in the surface, but, even with these slopes, ponding and water logging may occur. The slope may be provided by the floor, or benches or racks may hold the channels and provide the required slope. Both methods are used and depend on local requirements, often determined by the site and crop requirements.

As a general guide, flow rates for each gully should be 1 liter per minute. At planting, rates may be half this and the upper limit of 2 L/min appears about the maximum. Flow rates beyond these extremes are often associated with nutritional problems. Depressed growth rates of many crops have been observed when channels exceed 12 metres in length. On rapidly growing crops, tests have indicated that, while oxygen levels remain adequate, nitrogen may be depleted over the length of the gully. As a consequence, channel length should not exceed 10–15 metres. In situations where this is not possible, the reductions in growth can be eliminated by placing another nutrient feed halfway along the gully and reducing flow rates to 1 L/min through each outlet.

Aeroponics

Main article: Aeroponics

Aeroponics is a system wherein roots are continuously or discontinuously kept in an environment saturated with fine drops (a mist or aerosol) of nutrient solution. The method requires no substrate and entails growing plants with their roots suspended in a deep air or growth chamber with the roots periodically wetted with a fine mist of atomized nutrients. Excellent aeration is the main advantage of aeroponics.

Aeroponic techniques have proven to be commercially successful for propagation, seed germination, seed potato production, tomato production, leaf crops, and micro-greens.[11] Since inventor Richard Stoner commercialized aeroponic technology in 1983, aeroponics has been implemented as an alternative to water intensive hydroponic systems worldwide.[12] The limitation of hydroponics is the fact that 1 kg of water can only hold 8 mg of air, no matter whether aerators are utilized or not.

Another distinct advantage of aeroponics over hydroponics is that any species of plants can be grown in a true aeroponic system because the micro environment of an aeroponic can be finely controlled. The limitation of hydroponics is that only certain species of plants can survive for so long in water before they become waterlogged. The advantage of aeroponics is that suspended aeroponic plants receive 100% of the available oxygen and carbon dioxide to the roots zone, stems, and leaves,[13] thus accelerating biomass growth and reducing rooting times. NASA research has shown that aeroponically grown plants have an 80% increase in dry weight biomass (essential minerals) compared to hydroponically grown plants. Aeroponics used 65% less water than hydroponics. NASA also concluded that aeroponically grown plants requires ¼ the nutrient input compared to hydroponics. Unlike hydroponically grown plants, aeroponically grown plants will not suffer transplant shock when transplanted to soil, and offers growers the ability to reduce the spread of disease and pathogens. Aeroponics is also widely used in laboratory studies of plant physiology and plant pathology. Aeroponic techniques have been given special attention from NASA since a mist is easier to handle than a liquid in a zero gravity environment.

Passive sub-irrigation

Main article: Passive hydroponics

Passive sub-irrigation, also known as passive hydroponics or semi-hydroponics, is a method wherein plants are grown in an inert porous medium that transports water and fertilizer to the roots by capillary action from a separate reservoir as necessary, reducing labour and providing a constant supply of water to the roots. In the simplest method, the pot sits in a shallow solution of fertilizer and water or on a capillary mat saturated with nutrient solution. The various hydroponic media available, such as expanded clay and coconut husk, contain more air space than more traditional potting mixes, delivering increased oxygen to the roots, which is important in epiphytic plants such as orchids and bromeliads, whose roots are exposed to the air in nature. Additional advantages of passive hydroponics are the reduction of root rot and the additional ambient humidity provided through evaporations.

Ebb and flow or flood and drain sub-irrigation

Main article: Ebb and flow

In its simplest form, there is a tray above a reservoir of nutrient solution. Either the tray is filled with growing medium (clay granules being the most common) and planted directly or pots of medium stand in the tray. At regular intervals, a simple timer causes a pump to fill the upper tray with nutrient solution, after which the solution drains back down into the reservoir. This keeps the medium regularly flushed with nutrients and air. Once the upper tray fills past the drain stop, it begins recirculating the water until the timer turns the pump off, and the water in the upper tray drains back into the reservoirs.[14]

Run to waste

In a run to waste system, nutrient and water solution is periodically applied to the medium surface. This may be done in its simplest form, by manually applying a nutrient-and-water solution one or more times per day in a container of inert growing media, such as rockwool, perlite, vermiculite, coco fibre, or sand. In a slightly more complex system, it is automated with a delivery pump, a timer and irrigation tubing to deliver nutrient solution with a delivery frequency that is governed by the key parameters of plant size, plant growing stage, climate, substrate, and substrate conductivity, pH, and water content.

In a commercial setting, watering frequency is multi factorial and governed by computers or PLCs.

Commercial hydroponics production of large plants like tomatoes, cucumber, and peppers use one form or another of run to waste hydroponics.

In environmentally responsible uses, the nutrient rich waste is collected and processed through an on site filtration system to be used many times, making the system very productive.[15]

Deep water culture

Main article: Deep water culture

The hydroponic method of plant production by means of suspending the plant roots in a solution of nutrient-rich, oxygenated water. Traditional methods favor the use of plastic buckets and large containers with the plant contained in a net pot suspended from the centre of the lid and the roots suspended in the nutrient solution. The solution is oxygen saturated from an air pump combined with porous stones. With this method, the plants grow much faster because of the high amount of oxygen that the roots receive.[16]

Bubbleponics

"Bubbleponics" is the art of delivering highly oxygenated nutrient solution direct to the root zone of plants. While Deep Water Culture involves the plant roots hanging down into a reservoir of water below, the term Bubbleponics describes a top-fed Deep Water Culture (DWC) hydroponic system. In this method, the water is pumped from the reservoir up to the roots (top feeding). The water is released over the plant's roots and then runs back into the reservoir below in a constantly recirculating system. As with Deep Water Culture, there is an airstone in the reservoir that pumps air into the water via a hose from outside the reservoir. The airstone helps add oxygen to the water. Both the airstone and the water pump run 24 hours a day.

The biggest advantages with Bubbleponics over Deep Water Culture involve increased growth during the first few weeks. With Deep Water Culture, there is a time where the roots have not reached the water yet. With Bubbleponics, the roots get easy access to water from the beginning and will grow to the reservoir below much more quickly than with a Deep Water Culture system. Once the roots have reached the reservoir below, there is not a huge advantage with Bubbleponics over Deep Water Culture. However, due to the quicker growth in the beginning, a few weeks of grow time can be shaved off.[17]

Fogponics

Main article: Fogponics

Fogponics Fogponics is an advanced form of aeroponics which uses water in a vaporised form to transfer nutrients and oxygen to enclosed suspended plant roots. Using the same general idea behind aeroponics except fogponics uses a 5-10 micron mist within the rooting chamber and as use for a foliar feeding mechanism.

Rotary

A rotary hydroponic garden is a style of commercial hydroponics created within a circular frame which rotates continuously during the entire growth cycle of whatever plant is being grown.

While system specifics vary, systems typically rotate once per hour, giving a plant 24 full turns within the circle each 24 hour period. Within the center of each rotary hydroponic garden is a high intensity grow light, designed to simulate sunlight, often with the assistance of a mechanized timer.

Each day, as the plants rotate, they are periodically watered with a hydroponic growth solution to provide all nutrient necessary for robust growth. Due to the plants continuous fight against gravity plants typically mature much more quickly than when grown in soil or other traditional hydroponic growing systems. Due to the small foot print a rotary hydroponic system has, it allows for more plant material to be grown per sq foot of floor space than other traditional hydroponic systems.

Substrates

One of the most obvious decisions hydroponic farmers have to make is which medium they should use. Different media are appropriate for different growing techniques.

Expanded clay aggregate

Main article: Expanded clay aggregate

Baked clay pellets, are suitable for hydroponic systems in which all nutrients are carefully controlled in water solution. The clay pellets are inert, pHneutral and do not contain any nutrient value.

The clay is formed into round pellets and fired in rotary kilns at 1,200 °C (2,190 °F). This causes the clay to expand, like popcorn, and become porous. It is light in weight, and does not compact over time. The shape of an individual pellet can be irregular or uniform depending on brand and manufacturing process. The manufacturers consider expanded clay to be an ecologically sustainable and re-usable growing medium because of its ability to be cleaned and sterilized, typically by washing in solutions of white vinegar, chlorine bleach, or hydrogen peroxide (H

2O

2), and rinsing completely.

Another view is that clay pebbles are best not re-used even when they are cleaned, due to root growth that may enter the medium. Breaking open a clay pebble after a crop has been grown will reveal this growth.

Growstones

Growstones, made from glass waste, have both more air and water retention space than perlite and peat. This aggregate holds more water than parboiled rice hulls.[18]

Coir

Coco Peat, also known as coir or coco, is the leftover material after the fibres have been removed from the outermost shell (bolster) of the coconut. Coir is a 100% natural grow and flowering medium. Coconut Coir is colonized with trichoderma Fungi, which protects roots and stimulates root growth. It is extremely difficult to over water coir due to its perfect air-to-water ratio, plant roots thrive in this environment, coir has a high cation exchange, meaning it can store unused minerals to be released to the plant as and when it requires it. Coir is available in many forms, most common is coco peat, which has the appearance and texture of soil but contains no mineral content.

Rice Hulls

Parboiled rice hulls (PBH) decay over time. Rice hulls allow drainage,[19] and even retain less water than growstones.[18] A study showed that rice hulls didn't affect the effects of plant growth regulators.[19] Rice hulls are an agricultural byproduct that would otherwise have little use.

Perlite

Perlite is a volcanic rock that has been superheated into very lightweight expanded glass pebbles. It is used loose or in plastic sleeves immersed in the water. It is also used in potting soil mixes to decrease soil density. Perlite has similar properties and uses to vermiculite but, in general, holds more air and less water. If not contained, it can float if flood and drain feeding is used. It is a fusion of granite, obsidian, pumice and basalt. This volcanic rock is naturally fused at high temperatures undergoing what is called "Fusionic Metamorphosis".

Pumice

Like perlite, pumice is a lightweight, mined volcanic rock that finds application in hydroponics.

Vermiculite

Like perlite, vermiculite is a mineral that has been superheated until it has expanded into light pebbles. Vermiculite holds more water than perlite and has a natural "wicking" property that can draw water and nutrients in a passive hydroponic system. If too much water and not enough air surrounds the plants roots, it is possible to gradually lower the medium's water-retention capability by mixing in increasing quantities of perlite.

Sand

Sand is cheap and easily available. However, it is heavy, does not hold water very well, and it must be sterilized between use.

Gravel

The same type that is used in aquariums, though any small gravel can be used, provided it is washed first. Indeed, plants growing in a typical traditional gravel filter bed, with water circulated using electric powerhead pumps, are in effect being grown using gravel hydroponics. Gravel is inexpensive, easy to keep clean, drains well and will not become waterlogged. However, it is also heavy, and, if the system does not provide continuous water, the plant roots may dry out.

Wood fibre

Wood fibre, produced from steam friction of wood, is a very efficient organic substrate for hydroponics. It has the advantage that it keeps its structure for a very long time. Wood fibre has been shown to reduce the effects of "plant growth regulators."[19]

Sheep wool

Wool from shearing sheep is a little-used yet promising renewable growing medium. In a study comparing wool with peat slabs, coconut fibre slabs, perlite and rockwool slabs to grow cucumber plants, sheep wool had a greater air capacity of 70%, which decreased with use to a comparable 43%, and water capacity that increased from 23% to 44% with use. Using sheep wool resulted in the greatest yield out of the tested substrates, while application of a biostimulator consisting of humic acid, lactic acid and Bacillus subtilis improved yields in all substrates.[20]

Rock wool

Rock wool (mineral wool) is the most widely used medium in hydroponics. Rock wool is an inert substrate suitable for both run to waste and recirculating systems. Rock wool is made from molten rock, basalt or 'slag' that is spun into bundles of single filament fibres, and bonded into a medium capable of capillary action, and is, in effect, protected from most common microbiological degradation. Rock wool has many advantages and some disadvantages. The latter being the possible skin irritancy (mechanical) whilst handling (1:1000). Flushing with cold water usually brings relief. Advantages include its proven efficiency and effectiveness as a commercial hydroponic substrate. Most of the rock wool sold to date is a non-hazardous, non-carcinogenic material, falling under Note Q of the European Union Classification Packaging and Labeling Regulation (CLP).[citation needed]

Brick shards

Brick shards have similar properties to gravel. They have the added disadvantages of possibly altering the pH and requiring extra cleaning before reuse.

Polystyrene packing peanuts

Polystyrene packing peanuts are inexpensive, readily available, and have excellent drainage. However, they can be too lightweight for some uses. They are used mainly in closed-tube systems. Note that polystyrene peanuts must be used; biodegradable packing peanuts will decompose into a sludge. Plants may absorb styrene and pass it to their consumers; this is a possible health risk.[citation needed]

Nutrient solutions

Main article: Plant nutrition

Plant nutrients used in hydroponics are dissolved in the water and are mostly in inorganic and ionic form. Primary among the dissolved cations (positively charged ions) are Ca2+ (calcium),Mg2+

(magnesium), and K+

(potassium); the major nutrient anions in nutrient solutions are NO−

3 (nitrate), SO2−

4 (sulfate), and H

2PO−

4 (dihydrogen phosphate).

Numerous 'recipes' for hydroponic solutions are available. Many use different combinations of chemicals to reach similar total final compositions. Commonly used chemicals for the macronutrients include potassium nitrate, calcium nitrate, potassium phosphate, and magnesium sulfate. Various micronutrients are typically added to hydroponic solutions to supply essential elements; among them are Fe (iron), Mn (manganese), Cu (copper), Zn (zinc), B (boron), Cl (chlorine), and Ni (nickel). Chelating agents are sometimes used to keep Fe soluble, and humic acids can be added to increase nutrient uptake.[21] Many variations of the nutrient solutions used by Arnon and Hoagland (see above) have been styled 'modified Hoagland solutions' and are widely used. Variation of different mixes throughout the plant life-cycle, further optimizes its nutritional value.[22] Plants will change the composition of the nutrient solutions upon contact by depleting specific nutrients more rapidly than others, removing water from the solution, and altering the pH by excretion of either acidity or alkalinity.[23] Care is required not to allow salt concentrations to become too high, nutrients to become too depleted, or pH to wander far from the desired value.

Although pre-mixed concentrated nutrient solutions are generally purchased from commercial nutrient manufacturers by hydroponic hobbyists and small commercial growers, several tools exists to help anyone prepare their own solutions without extensive knowledge about chemistry. The free and open source tools HydroBuddy[24] and HydroCal[25] have been created by professional chemists to help any hydroponics grower prepare their own nutrient solutions. The first program is available for Windows, Mac and Linux while the second one can be used through a simple Java interface. Both programs allow for basic nutrient solution preparation although HydroBuddy provides added functionality to use and save custom substances, save formulations and predict electrical conductivity values.

The well-oxygenated and enlightened environment promotes the development of algae. It is therefore necessary to wrap the tank with black film obscuring all light.

Organic hydroponics uses the solution containing microorganisms. In organic hydroponics, organic fertilizer can be added in the hydroponic solution because microorganisms degrade organic fertilizer into inorganic nutrients. In contrast, conventional hydroponics cannot use organic fertilizer because organic compounds in the hydroponic solution show phytotoxic effects.

Commercial

Some commercial installations use no pesticides or herbicides, preferring integrated pest management techniques. There is often a price premium willingly paid by consumers for produce that is labelled "organic". Some states in the USA require soil as an essential to obtain organic certification. There are also overlapping and somewhat contradictory rules established by the US Federal Government, so some food grown with hydroponics can be certified organic. Most hydroponically grown produce cannot be sold as organic due to the fact that they do not use soil as a growing medium.

Hydroponics also saves water; it uses as little as 1⁄20 the amount as a regular farm to produce the same amount of food. The water table can be impacted by the water use and run-off of chemicals from farms, but hydroponics may minimize impact as well as having the advantage that water use and water returns are easier to measure. This can save the farmer money by allowing reduced water use and the ability to measure consequences to the land around a farm.

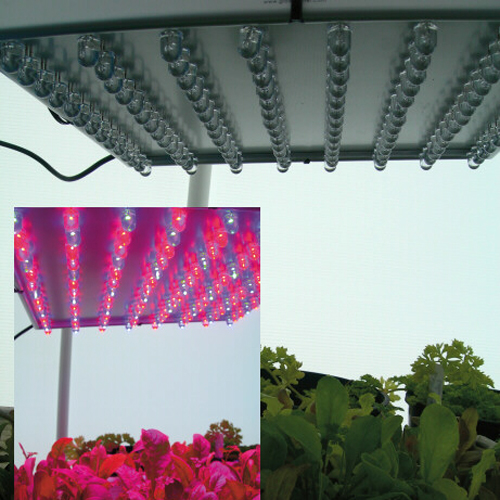

To increase plant growth, lighting systems such as metal-halide lamp for growing stage only or high-pressure sodium for growing/flowering/blooming stage are used to lengthen the day or to supplement natural sunshine if it is scarce. Metal halide emits more light in the blue spectrum, making it ideal for plant growth but is harmful to unprotected skin and can cause skin cancer. High-pressure sodium emits more light in the red spectrum, meaning that it is best suited for supplementing natural sunshine and can be used throughout the growing cycle. However, these lighting systems require large amounts of electricity to operate, making efficiency and safety very critical.

The environment in a hydroponics greenhouse is tightly controlled for maximum efficiency, and this new mindset is called soil-less/controlled-environment agriculture (CEA). With this growers can make ultra-premium foods anywhere in the world, regardless of temperature and growing seasons. Growers monitor the temperature, humidity, and pH level constantly.

Hydroponics have been used to enhance vegetables to provide more nutritional value. A hydroponic farmer in Virginia has developed a calcium and potassium enriched head of lettuce, scheduled to be widely available in April 2007. Grocers in test markets have said that the lettuce sells "very well", and the farmers claim that their hydroponic lettuce uses 90% less water than traditional soil farming.[26]

Advancements

With pest problems reduced, and nutrients constantly fed to the roots, productivity in hydroponics is high, although plant growth can be limited by the low levels of carbon dioxide in the atmosphere, or limited light exposure. To increase yield further, some sealed greenhouses inject carbon dioxide into their environment to help growth (CO

2 enrichment), add lights to lengthen the day, or control vegetative growth, etc.